What are the advantages of a Corrugated Plastic Container compare to Corrugated Paper boxes?

The first benefit would be the durability of Corrugated Plastic Container over Paper Corrugated. Plastic Corrugated doesn’t mind high humidity environments and in the possible case of water damage, your Plastic Corrugated container will help prevent your papers from being damaged. Unlike paper corrugated our Plastic Corrugated Containers will not loose stacking strength in humid environments. And it is washable.

Another benefit is that Plastic Corrugated is archive safe. Paper Corrugated contains acids that can damage documents and other delicate items like artwork. Plastic Corrugated is also beneficial in cleanroom applications as it does not have fiber dust like paper corrugated containers contain. It has been widely accepted by libraries, museums, banks, and government institutes.

It has an unlimited shelf life and the ability to store your documents safely for years to come. Corrugated plastic container is a perfect alternative and actual upgrade to any paper corrugated container.

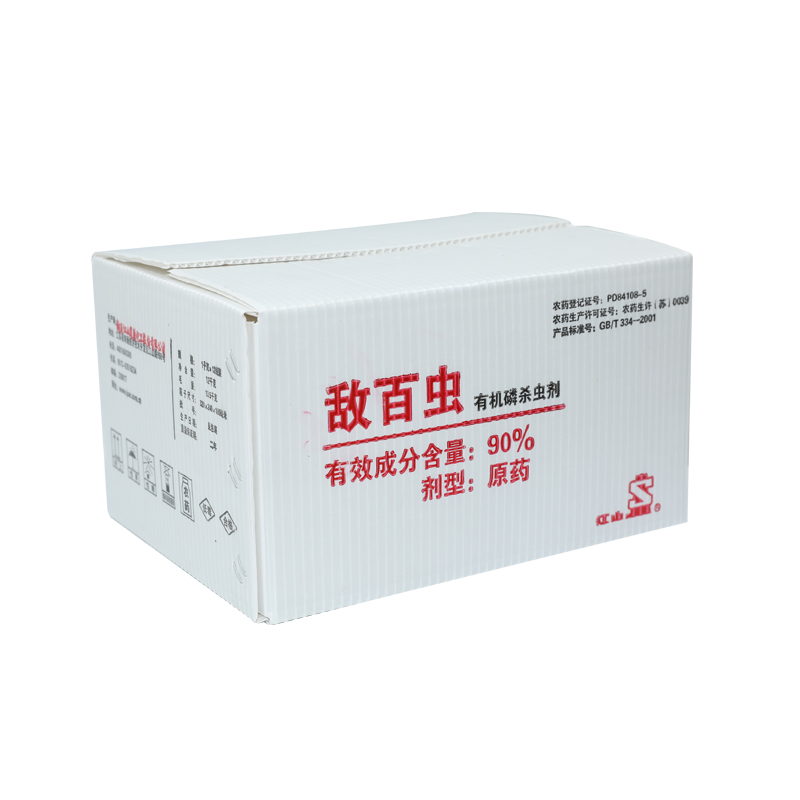

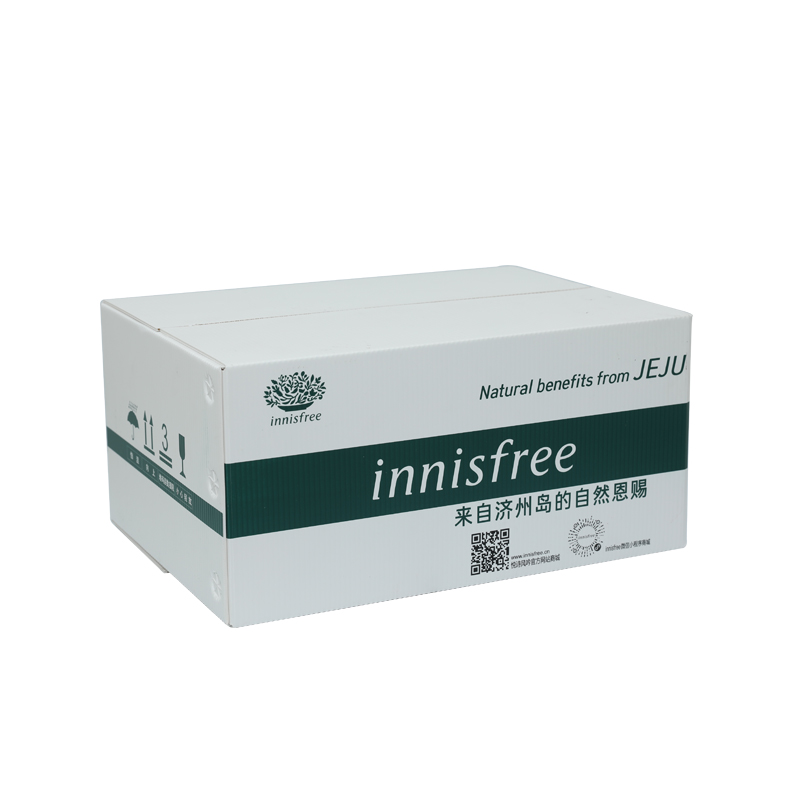

We can customize colors, printings, sizes, and designs to meet all your requirements.

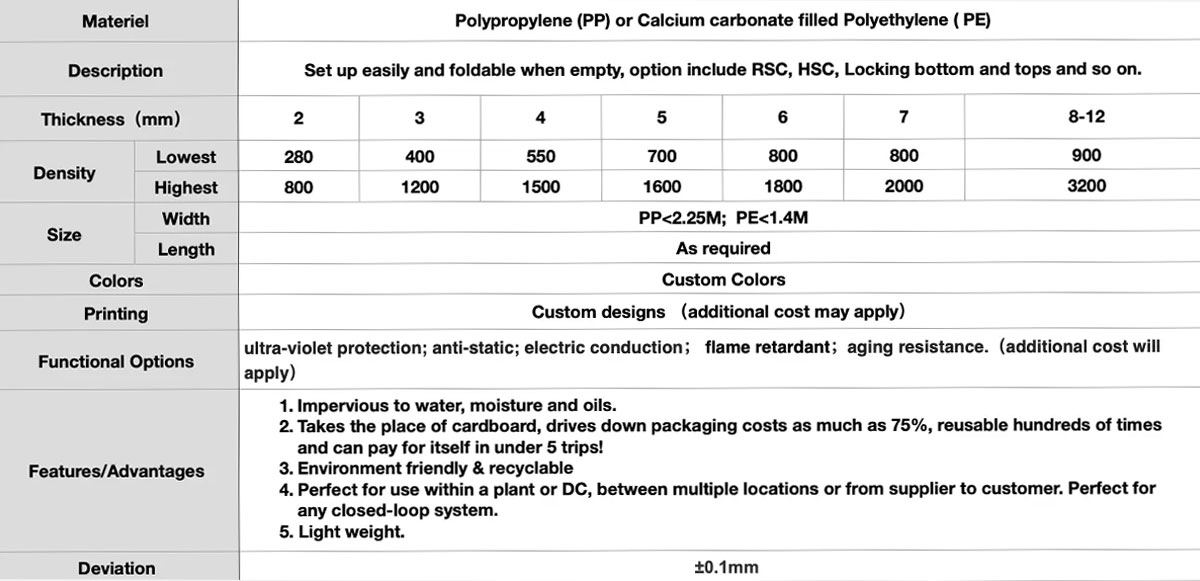

Should I use Polypropylene(PP) or Polyethylene(PE) plastic corrugated for my container?

Polypropylene or Polyethylene is the two different types of resin used when producing plastically corrugated. The most common throughout the plastic corrugated industry is PP when producing products or sheets in I-Beam(also known as H-Beam) structure material. The I-Beam plastic corrugated material can also be produced in PE when required. When producing containers or sheets in plastic corrugated laminated (Wave-Beam) structure it will always be made from polyethylene. The most common thickness for PE laminated (Wave-Beam) is 4mm.

Polypropylene vs Polyethylene Plastic Corrugated

Depending on how you are going to use your product. PE is less affected by extreme cold applications. When the temperatures reach 10℃ or lower PP will begin to have a tendency or at least more likely to fracture or crack when it takes an impact or when flexed or folded in this cold environment.

PE is also softer, so it may be selected or rejected for the project because of this factor. The warmer the environment the softer polyethylene will become.

PE plastic corrugated sheet more “shinning and smooth” than PP plastic corrugated sheet.

Both materials have their benefits and deficits. So each project needs to be evaluated before making a decision.

WHY US?

* Leading manufacturer with 20 years experiences

* Sold tens of millions of containers

* Professional team and services

* Top quality and attractive price

• Please note that all products will need to be manufactured at the time of order.

• The sizes, designs and colors might be different for each customer, so please let us know your requirements and circumstances it will be used, we will give appropriate suggestions based on our experience.

• It normally takes 1-2 weeks for manufacturing "standard"products since we receive deposit.

• For large quantity orders or complex printings and designs, please contact us for more details.

• To choose PP extruded profile material or HDPE Laminated material, It depends on the project and design of your product. Both materials have their benefits and some deficits.

A1: La quantité minimum de commande est de 500 pièces. Cependant, il pourrait ne pas être rentable sur les frais de port pour les petites commandes.

A2: Bien sûr, veuillez noter que le transport sera à vos frais et devra être payé à l'avance.

A3: Nous acceptons toutes les commandes OEM. Veuillez nous contacter pour plus de détails.

A4: Par T / T, dépôt de 50% à l'avance, solde 50% avant expédition.

A5: Nous répondons généralement à votre demande dans les 24 heures. Les tailles, les conceptions et les couleurs peuvent être différentes pour chaque client, veuillez donc nous faire part de vos besoins et des circonstances dans lesquelles il sera utilisé, nous vous donnerons des suggestions appropriées basées sur notre expérience et un devis pour vous.